Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

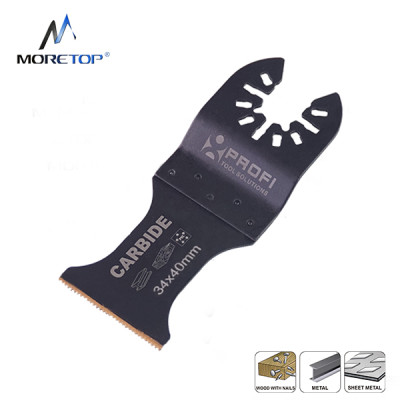

OSCILLATING CUTTING BLADES

Features:

·PROFI Multi-Tool Blades are designed for a multitude of DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

·Our Universal Quick Fit Blades are suitable for all customers’ Oscillating Multi-Tool and make you change the blades quickly.

30 results

ViewShowcase

Our latest EXPERT oscillating blade with curved carbide edge—designed to deliver professional-grade performance on every cut.

MORETOP oscillating multi tool blade with whole carbide teeth can easily handle the toughest metal applications.

The semicircular curve design creates precise, clean plunge cuts with less vibration.

Moretop oscillating blades are universal fit blades with application-specific designs that provide maximum durability and longer life in metal.

Moretop oscillating blades are universal fit blades with application-specific designs that provide maximum durability and longer life in metal.

Moretop oscillating blades are universal fit blades with application-specific designs that provide maximum durability and longer life in metal.

Ideal for cutting nail embedded timber, copper pipe, hard wood, sheet metal, plastics and aluminum.

Ideal for cutting nail embedded timber, copper pipe, hard wood, sheet metal, plastics and aluminum.

Ideal for cutting nail embedded timber, copper pipe, hard wood, sheet metal, plastics and aluminum.

A universal fit arbor ensures compatibility with all open-back oscillating tools.

A universal fit arbor ensures compatibility with all open-back oscillating tools.

MORETOP oscillating multi tool blade is suitable for professionals and DIYers.

MORETOP oscillating multi tool blade with whole carbide teeth can easily handle the toughest metal applications.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

moretop oscillating multi-tool carbide teeth plunge cut blade

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop multi tool blades are used for DIY jobs such as cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

The Moretop Blades are used for DIY jobs such as sawing, cutting, scraping, shoveling, grinding or removing, residues.

moretop oscillating multi-tool curved bi-metal plunge cut blade

The Moretop multi tool blades are used for DIY jobs such as cutting, scraping, shoveling, grinding or removing, residues.

moretop oscillating multi-tool curved bi-metal plunge cut blade

Oscillating Cutting Blades Overview:

Oscillating cutting blades are specialized tools designed for precision cutting in various materials. With their oscillating motion and sharp teeth, these blades provide accurate and controlled cutting for a wide range of applications. From wood and metal to plastic and drywall, oscillating cutting blades are essential tools for DIY enthusiasts, contractors, and craftsmen who require versatility and precision in their cutting tasks.

Features of Oscillating Cutting Blades:

Versatile Cutting: Oscillating cutting blades are compatible with a variety of oscillating tools, making them suitable for cutting different materials, including wood, metal, plastic, drywall, and more. They are capable of making plunge cuts, straight cuts, flush cuts, and intricate cuts with precision.

Oscillating Motion: The oscillating motion of the blades enables precise control and reduced vibration during cutting, resulting in cleaner and more accurate cuts.

Blade Variety: Oscillating cutting blades come in various shapes, sizes, and tooth patterns to suit different cutting needs. From fine-tooth blades for detailed cuts to coarse-tooth blades for faster cutting, there is a blade option for every application.

Quick Blade Change: Many oscillating tools feature a tool-free blade change system, allowing for easy and efficient swapping of blades to match specific cutting requirements.

Durability: These blades are constructed from high-quality materials such as high-speed steel (HSS), bi-metal, or carbide, ensuring durability and longevity even during demanding cutting tasks.

Maintenance and Care for Oscillating Cutting Blades:

To ensure optimal performance and extend the lifespan of your oscillating cutting blades, consider the following maintenance tips:

Clean the blades after each use to remove debris and buildup. Use a brush or compressed air to clear out any material that may affect cutting performance.

Lubricate the blade shaft regularly to reduce friction and enhance the blade's cutting efficiency.

Inspect the blades for signs of wear or damage, such as dull teeth or chips. Replace worn-out blades to maintain optimal cutting performance and prevent accidents.

Safety Tips for Using Oscillating Cutting Blades:

When working with oscillating cutting blades, prioritize safety using these guidelines:

Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a dust mask to protect against flying debris and dust.

Secure the workpiece properly before starting the cutting task to ensure stability and prevent accidents.

Use light pressure and let the blade do the cutting. Avoid applying excessive force, which can lead to blade deflection or damage.

Keep your hands and fingers clear of the cutting path and ensure a firm grip on the tool for better control and safety.

Disconnect the power source before changing or adjusting the blades.

Application Guide for Oscillating Cutting Blades:

Oscillating cutting blades are versatile tools suitable for a wide range of cutting applications, including:

Precision Cutting: These blades excel at making precise cuts in materials such as wood, metal, plastic, drywall, and more. They are ideal for tasks such as plunge cuts, straight cuts, trim work, and detailed cuts.

Flush Cutting: Oscillating cutting blades with flush-cut design allow for cutting close to surfaces, such as removing protruding nails or cutting door jambs.

Notching and Trimming: These blades are great for creating notches, slots, or grooves in various materials. They can also be used for trimming pipes, baseboards, or other narrow areas.

Tile and Grout Removal: With the appropriate blade attachment, oscillating cutting blades can effectively remove tile adhesive, grout, or caulk during renovation or repair projects.

Material Shaping: Oscillating cutting blades can be used for shaping or sculpting materials like wood, creating bevels, or making precision cuts for custom installations.

Choosing the Right Oscillating Cutting Blade:

Selecting the appropriate oscillating cutting blade for your specific application is crucial. Consider the following factors:

Material Compatibility: Ensure the blade is suitable for the material you intend to cut. Different blade types and tooth patterns are designed for specific materials.

Blade Size and Shape: Choose a blade that fits your oscillating tool and allows for easy access to the cutting area, especially for tight spaces or intricate cuts.

Tooth Pattern: Consider the tooth pattern (e.g., fine, coarse, or segmented) based on the desired cutting speed, aggressiveness, and finish quality.

Blade Durability: For demanding cutting tasks or frequent use, opt for blades made from high-quality materials such as carbide or bi-metal for enhanced durability.

By understanding the features, maintenance, safety precautions, applications, and selection guidelines for oscillating cutting blades, you can achieve precise, efficient, and safe cutting results across various materials and projects. Choose the right blade for your specific needs and unleash the versatility of your oscillating tool.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool