Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

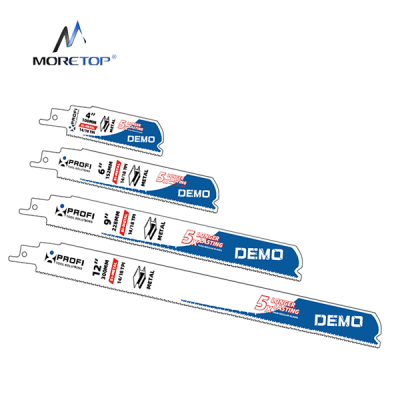

RECIP BLADES

Features:

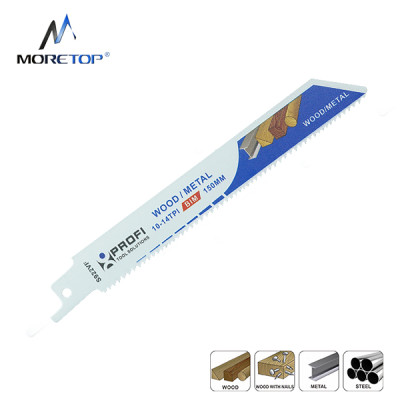

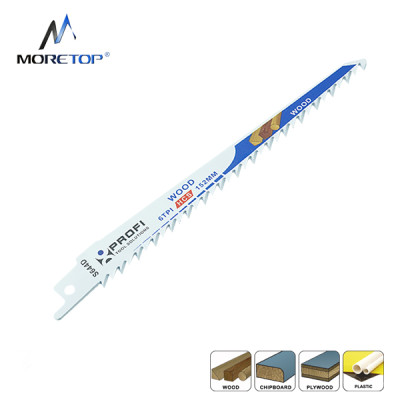

·Recip saw blades are have a universal shank to fit all types of reciprocating saw, Black&Decker, Bosch, Makita, ...... Used for wood cutting, metal cutting, nail embedded

·wood cutting and demolition.

22 results

ViewShowcase

We're proud to introduce our newest heavy-duty cutting solution — the MORETOP Expert Reciprocating Saw Blade

Looking for a smarter way to clean tough surfaces?

Our Reciprocating Carbon Steel Wire Brush is engineered for precision and versatility.

Our Reciprocating Carbon Steel Wire Brush is engineered for precision and versatility.

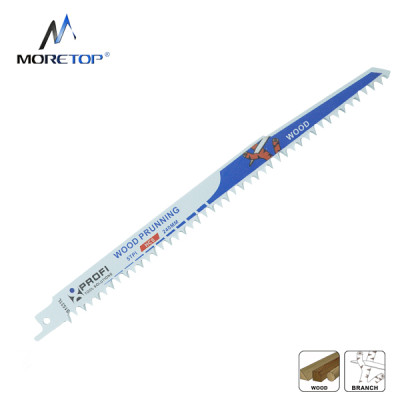

We're excited to introduce our latest innovation — the new Curved Branch Saw, wood pruuning saw blade!

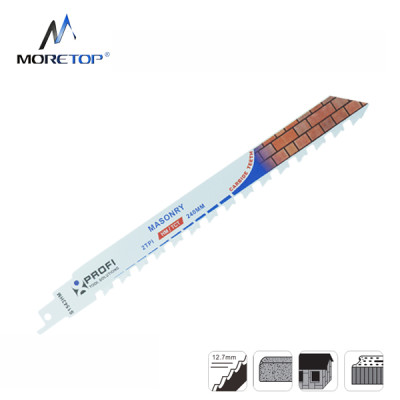

MORETOP carbide reciprocating blades provides ultimate flexibility and impact strength needed for heavy duty demolition work.

MORETOP carbide reciprocating blades provides ultimate flexibility and impact strength needed for heavy duty demolition work.

Moretop metal cutting reciprocating saw blade have longer life, providing customers with a more cost-effective choice.

Reciprocating saw blades with Full Contact Arched Design are designed for maximum performance in metal cutting applications.

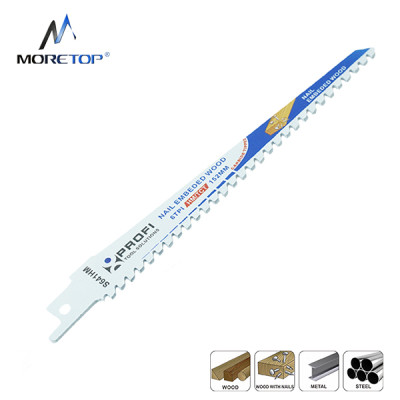

Moretop's reciprocating saw blades are specifically designed for maximum performance in nail-embedded wood applications.

High performance carbide for greater durability in sheet metal/wood with nails/plastic profiles

Moretop Reciprocating Saw Blades are ideal for cutting sheet metal, wood with embedded nails, and plastic profiles.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice

Overview of Recip Blades

Recip blades, short for reciprocating saw blades, are essential cutting tools used with reciprocating saws. These blades feature a straight back and a toothed edge, allowing them to rapidly move back and forth to cut through various materials. With their versatility and cutting efficiency, recip blades are widely used in construction, demolition, remodeling, and woodworking projects.

Types and Features of Recip Blades

Recip blades come in different types, each designed for specific cutting applications. Here are some common types and their features:

Wood Cutting Blades: These blades have large, widely spaced teeth for fast and efficient cutting through wood and wood-based materials. They are suitable for general woodworking tasks, including rough cuts and pruning.

Metal Cutting Blades: Metal cutting recip blades are designed with smaller, closely spaced teeth to cut through various metals, such as steel, aluminum, and copper. They offer precise and clean cuts in metal fabrication, automotive repairs, and plumbing projects.

Demolition Blades: Demolition recip blades feature rugged construction with reinforced teeth, enabling them to withstand tough materials like nails, screws, and thick lumber. These blades are ideal for demolition and remodeling projects, where cutting through a variety of materials is required.

Bi-Metal Blades: Bi-metal recip blades are constructed with two different types of metals, typically high-speed steel (HSS) teeth combined with a flexible and durable backing. This design offers enhanced cutting performance, durability, and resistance to breakage, making them suitable for versatile cutting tasks.

Carbide-Tipped Blades: Carbide-tipped recip blades are engineered with carbide teeth, which provide exceptional cutting performance and longevity. These blades are specifically designed for cutting abrasive materials like ceramic tiles, masonry, and fiberglass.

Maintenance and Care Tips for Recip Blades

To maximize the lifespan and cutting performance of your recip blades, consider the following maintenance tips:

Clean the Blades: After each use, remove any debris or residue from the blades using a wire brush or compressed air. This helps prevent buildup and ensures optimal cutting efficiency.

Blade Lubrication: Applying a lubricant or cutting fluid to the blades can reduce friction, prevent overheating, and enhance the cutting performance. Check the manufacturer's recommendations for compatible lubricants.

Blade Storage: Store recip blades in a clean and dry environment to prevent rust or corrosion. Consider using blade containers or magnetic blade holders for organized storage.

Safety Guidelines for Working with Recip Blades

When using recip blades, it's essential to prioritize safety. Adhere to the following guidelines:

Wear Personal Protective Equipment (PPE): Always wear safety goggles, gloves, and hearing protection to protect against flying debris, vibrations, and noise.

Secure Workpieces: Ensure the workpiece is properly clamped or secured before cutting to prevent unexpected movements or accidents.

Choose the Right Blade: Select the appropriate recip blade for the material you are cutting. Using the correct blade ensures efficient cutting and reduces the risk of blade breakage or damage.

Choosing the Right Recip Blades

Consider the following factors when choosing recip blades:

Material Compatibility: Determine the materials you frequently work with and choose recip blades specifically designed for those materials.

Teeth per Inch (TPI): Different TPI configurations are available for recip blades, with higher TPI providing smoother cuts in thinner materials, while lower TPI offers faster cuts in thicker materials.

Blade Length: Select the appropriate blade length based on the depth of the cuts you need to make.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool