Reciprocating Saw tutorial: Basics, operations and applications

Pick out the proper circular saw blade

We have written about table noticed blade height, the usage of miter saws, desk saw protection guidelines and circular saw blade preservation, however with so many styles of circular saw blades to pick from, how precisely do you pick out the proper process? Even if you understand a way to use a miter noticed like a seasoned, there are plenty of blades to pick out from. There are blades with lots of teeth and blades with few enamel, blades and not using a enamel like continuous flanges, blades with wide cuts and skinny cuts, with terrible front angles and positive the front angles, and so-known as all-reason blades that can be truely messy. So we have pooled all our wits and powers of simplicity to offer you with this useful manual to choosing the proper circular noticed blade.

The article primarily based on

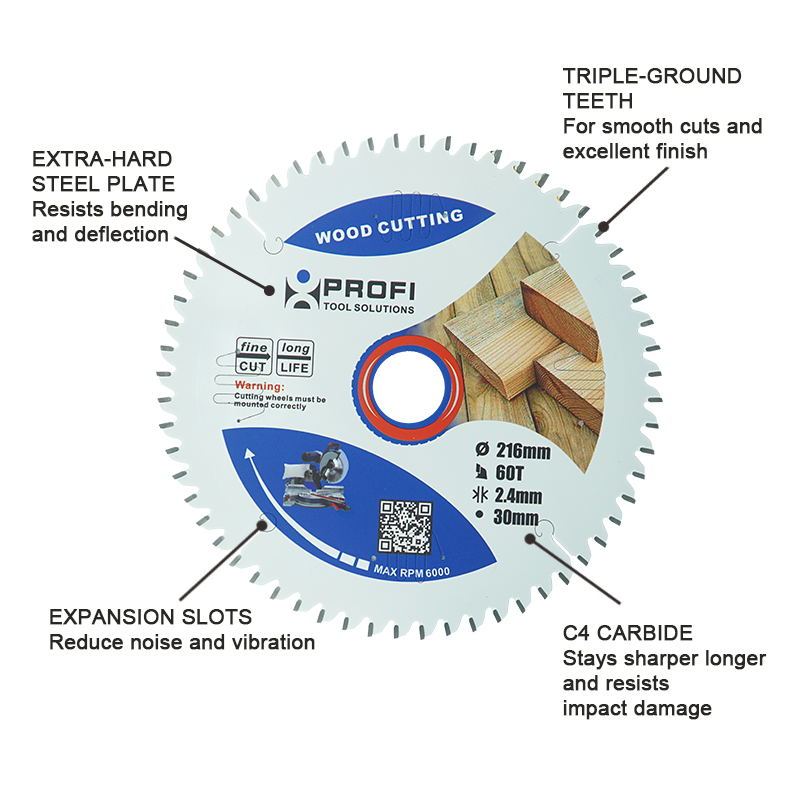

The quantity of teeth will have an effect on the cutting velocity and cleanness of the cutting

Large blades could have more ordinary enamel but the variety of teeth in step with inch (TPI) is identical

Esophagus length affects the blade's capacity to "take away" debris

Superb rake or rake slicing is greater competitive

The higher bevel produces a smoother reduce

Thinner cuts reduce faster (and greater efficiently), but may additionally introduce blade swing

Quantity of tooth

Normally, blades with greater enamel will offer a smoother, finer cut while blades with fewer teeth will offer a rougher cut. The benefit of fewer tooth is faster reducing and a decrease charge. For maximum creation work, a 24-tooth trendy use blade is sufficient. That blade could be very competitive and will help you rip and move-cut lumber and Sheet items fast and with a high degree of accuracy. With a 24-tooth demo blade, you are getting work done quickly, but you may not get a near-completed side.

Also, remember the fact that our 24-teeth instance is for a 7-1/4 "blade. The identical guider can be observed in a forty-tooth blade when you step up to a 12 "miter noticed blade. It is now not a lot the enamel be counted so much because the wide variety and length of tooth per linear inch of the noticed blade. Preserve that during mind as you store. A extra delicate thin kerf completing blade might be extra appropriate while reducing hardwood and trim in situations where you need a much cleaner part.

In preferred, the higher the teeth matter (consistent with blade diameter) the smoother the cut could be. It also approach, but, that the saw will want to exert extra force, And the cut could be slower on average. For a 7-1/4 "circular saw like the circular noticed, slower a forty tooth blade or better will give you a cleanser reduce, but you do not want to apply that for cross-cutting 2×four lumber on a task site.

Gullet size

The gullet is the distance among the enamel, the size and depth of which decide how plenty waste cloth is cleared out as the blade spins. You could quickly see that the gullet size is a feature of the range of tooth.

Hook or Rake angle

Diablo Framing Blade with tracking point

Hook or rake is the position of the tooth because it contacts the reducing surface. A high quality angle points down closer to the timber's floor aggressively removing waste material, resulting in a faster however rougher reduce.

Effective hook angles can cause what is called a climb cut or self-feeding as it has consequences the fabric in. There are applications -- like steel cutting -- wherein a positive hook may be very dangerous.

As you might imagine, bad hook or rakes reduce much less aggressively and don't self-feed which creates a smoother end, however they also may not cut as fast or do away with as a whole lot waste. You may locate metallic cutting blades and distinctiveness timber blades that use a poor rake angle.

Bevel

This critical differentiating component is the enamel attitude that cuts throughout or rotates perpendicular to the blade. The higher the bevel, the cleaner and smoother the reduce. A few blades have very excessive bevel angles and are used to cut composite materials which include melamine or different substances with thin veneers that tear/shatter effortlessly while the teeth leave the material. Bevels may be flat (no angles), alternating, noticeably alternating, or different configurations we can discuss below.

Diablo body blade with tracking factors

Incision

This is the width of the tooth at its widest point and consequently the width of the incision. At the beginning, you might have guessed that the thinner cut was designed for finer woodworking, but it was at the start developed for less effective worksites or portable saws. We reviewed the ultra-quality, skinny 12-inch diagonal noticed blades and observed that there has been loads to say approximately the numerous enamel geometry and vibration reduction techniques used in those blades.

Thinner cuts create much less resistance at some stage in slicing and are consequently better perfect to the power needs of these saws. But, the tradeoff is that the thinner blade vibrates or oscillates and reasons the slicing to reveal blade motion. These blades are especially troublesome in cutting hardwood.

Thin notched blade segments had been improved with new blade technology designed to reduce vibration (cordless round saw users have a good time!). .

Round reasoning

Now that we've got laid the groundwork, it have to be less difficult to determine what form of blade you want to apply for the task handy. Most importantly, determine the general form of slicing you will make - slicing throughout the texture or slitting alongside the feel. What kind of cut do you want - hard or easy?

Those questions are without problems spoke back through the usage of herbal wood with fibers extending inside the equal course. However bear in mind, composites don't have any fiber orientation -- so you may not crosscut or tear. It's also important to make certain that the blade you choose is particularly designed for the form of saw, power functionality and material you're reducing. Select the right accent for the task - certain styles of blades are device-specific.

Tear the blade

It can be more critical to select the proper round saw blade for cutting. Those blades have a small variety of tooth (commonly approximately 24) and almost no bevel. Tearing apart a chunk of wooden usually does now not require a fine, easy finished reduce. You can later shop the blades with higher teeth and bevel as the very last length. These blades will clear a whole lot of material quick, but it will be tough, and that is okay. This isn't always to mention which you can not tear with a generic or blended 40 or 50 enamel blade.

Go-slicing blades

Everybody who has used a router on an give up texture or reduce a dado on a timber fiber will tell you how the drill can cause a tear as it leaves the wooden (without proper generation or precautions, of course!). Round blade lacerations are not any exception. Crosscut blades have a better enamel depend (60 to 100) and a steep bevel to save you tearing.

Moretop plunge saw blades are specially designed for different plunge saws like Festool, Dewalt, Bosch, Mafell.

moretop vacuum brazed diamond blades, Vacuum brazing technology could attach large pieces of diamond grit to the cutting edge.